A manufacturing company worldwide is searching for the next best location to set up operations in light of the US-China trade conflict. However, only a few nations, like Vietnam, have the required human capital and infrastructure to set up manufacturing companies in Asia.

India, one of the world’s fastest-growing economies, had been a strong contender. However, Bloomberg reports that the nation’s workforce participation rate is among the lowest worldwide since 2014 (the Centre for Monitoring Indian Economy reported 40%). Moreover, in the past 8 years, the GOI (Government of India) has not taken any significant steps to improve its industrial policy.

Investing in Vietnam? Check out InCorp Vietnam’s Incorporation Services

Currently, Vietnam is not just a great place for manufacturing textiles and footwear, but it is also home to electronics, machinery, and automotive manufacturing. Vietnam stands out due to its stable political environment, a wealth of natural resources, cooperative government, and cheap but skilled workforce.

Made In Vietnam: How Vietnam Can Overtake India to be the World’s Manufacturing Hub

According to experts, by taking a more nationalistic stance, India is losing out on approx. US$28 trillion in potential global trade. This propensity toward inwardness results from the belief that domestic demand alone can sustain a 1.4 billion-person economy.

However, Vietnam is implementing the open and frictionless trade strategy used by the East Asian Tiger nations. So, despite having a far smaller population than India, the country is expanding its market share in international trade.

Read Related: Vietnam as an Emerging Manufacturing Hub in Asia-Pacific

Top Manufacturing Industries to Start a Company in Vietnam

Electronics

Electronics producers worldwide are increasingly turning to Vietnam to produce their goods in recent years. For instance, Xiaomi Corp. declared that it had begun manufacturing smartphones in Vietnam to increase its regional presence. Similarly, the production of smartphones by Samsung Electronics contributed US$57.5 billion to the nation’s exports in 2021.

According to the General Statistics Office, the electronics industry exported goods worth US$116 billion in 2021. Handsets and component exports totaled US$57.5 billion, while electronic, computer, and component exports came in at US$50.8 billion, up 11.5% and 13.6% from the prior year.

Read Related: Exploring Vietnam’s US$116 Billion Electronics Industry

Many of the biggest technology companies in the world, including Samsung, Foxconn, Canon, LG, and Intel, operate factories in Vietnam.

Major tech companies have significantly influenced the nation’s electronics industry (EI) growth. Vietnam is the world’s 12th-largest exporter of electronics, largely due to foreign direct investment (FDI), which accounts for a large chunk of the country’s EI value.

Garments

According to the Vietnam Textile & Apparel Association (VITAS), the country’s textile and apparel export revenue reached US$40.4 billion in 2021 and is projected to reach US$45 billion by the end of 2022.

For the past five years, the Vietnamese textile and apparel industry has maintained a strong growth rate, averaging between 20 – 26% annually.

The country is listed third among countries with the highest global textile and apparel export turnover. 5.2% of the worldwide textile and apparel market comprises goods shipped from Vietnam.

As of early 2022, Vietnam has displaced China as Nike, Inc.’s primary production location for footwear. Meanwhile, Nike’s financial report for 2021 shows that 51% of its footwear was created in Vietnam. Simultaneously, as per CNA, production in China declined to 21% from 35% in 2006.

Food Processing

Recent years have seen a lot of M&A activity in the food processing sector in Vietnam, leading to the emergence of “giants” (e.g. Pan Group, Thanh Cong, Kido, and Masan) and active investment from Thailand and Korea’s most prominent names in the FMCG (fast-moving consumer goods) sector.

According to reports, there are still potential investment prospects in Vietnam’s food processing business, particularly in the dairy and beverage sectors.

The import turnover for prepared and preserved seafood items was US$14.1 million in Q1 2020, a 5% decrease from the previous year. At the same time, nearly US$6.38 million worth of processed beef products were sold, a 16% decrease compared to the same time in 2019.

These numbers can be attributed to the disruption in trading activities and the significant decline in domestic demand due to COVID-19.

In Q1 2020, there were 48,000 tons of agriculturally processed food in stock. At almost 43,000 tons, coffee, pepper, and cashews had the biggest stock quantity, followed by seafood items. As a result, the food processing sector, which recorded a 96% increase over the first six months of 2020, was among the six sectors with the highest inventory index.

Businesses that invest in high-quality processing technology play a crucial role in boosting the agriculture sectors and realizing the nation’s growth objectives. The industry for processing agricultural products in Vietnam will rank among the top 10 in the world by 2030. The country will also act as the global logistics and processing hub with the capacity to meet the requirements of agricultural production.

Automobiles

The vehicle sector in Vietnam is expanding, making it a lucrative market for all foreign investors. This market’s average annual growth rate is between 20 – 30%, exceeding the Ministry of Industry and Trade’s expectations. The growth can be attributed to the importation of automobiles owned by foreigners and the brand-new Vietnamese automobile manufacturer, VinFast, which is generating headlines worldwide.

In 2018, VinFast attracted a lot of attention when it unveiled the 1st “made-in-Vietnam” car at the Paris Motor Show. With the goal of a sustainable, green future, VinFast is striving to bring accessible electric vehicles (EVs) to Vietnam.

The People’s Committee of Ha Tinh Province, in partnership with Vingroup, has started constructing the VinES Battery Manufacturing Factory worth around USD 173 million.

Vietnam imported more than 100,000 cars in the first nine months of 2021, a 267% increase from the year before. Most of the imported vehicles had fewer than nine seats, indicating a rise in the use of private cars and highlighting the rising spending power among the Vietnamese.

Moreover, Vietnam’s Ministry of Finance proposed a tax policy in November to lower or remove taxes on domestically produced car components. This would lower the total production costs and encourage investment in the country’s vehicle industry. The Ministry also advocated lower taxes for automakers and the industries supporting them.

The agreement will expose Vietnam’s automobile industry to important European auto markets like Germany, France, and the United Kingdom. In addition, the government has agreed to remove all import duties over the following 7 to 10 years on automotive exports from the EU to Vietnam, comprising vehicles and auto components.

Setup Guide for Manufacturing Companies

Choosing a Company Structure

Foreigners can establish a 100% foreign-owned business in Vietnam, but it can be started only as a Limited Liability Company/LLC or a Joint Stock Company/JSC.

- Limited Liability Companies or LLCs: LLCs are ideal for FDI in small-to-medium enterprises and can be started in just 45 days.

- Joint Stock Corporations or JSCs: JSCs have no specified upper limit regarding the number of shareholders and can be set up by individuals or companies.

- Representative Offices: A representative office permits sponsorships, recruiting, and promotional undertakings.

- Branch Office: A branch office in Vietnam becomes part of your brand’s international network. It operates in sync with its parent company abroad, eliminating the need for a separate legal entity – but you still need a legal representative to set it up.

Steps of Registering a Manufacturing Company in Vietnam (2023 Update)

International investors should carefully follow each of the stages listed below to fully comply with Vietnam’s requirements for registering international corporations.

- Decide on the factory’s location. The factory’s location can be outside or within industrial parks, high-tech zones, economic zones, and export processing zones.

- Provide the documentation for your business and employees.

- Set up a business address and locate a legal agent.

- Secure the Department of Planning and Investment’s Investment Registration Certificate (IRC).

- Obtain a certificate of enterprise registration (ERC).

- Put a company seal in the text (essential to authorize all issued documents).

- Create a bank account that contains the money you have to invest.

- Register for taxes and get an electronic sign (this is required for e-invoicing).

- Extra licenses may be necessary depending on your manufacturing product types, business lines, and if the process would cause any environmental impact. These additional licenses take 10 to 30 days to complete.

Conclusion

This article discusses the process of setting up a manufacturing company in Vietnam. It highlights the importance of obtaining the necessary (especially the IRC and ERC), providing a detailed company structure, and conducting due diligence to ensure compliance with local regulations. Furthermore, it suggests that foreign companies should consider joint ventures with local partners, choose the right location for their business, and be aware of land and labor regulations. It also emphasizes that outsourcing to a reliable local consultant can simplify the process and reduce investment risk.

Invest in this innovative emerging manufacturing hub to take advantage of Vietnam’s electronics, clothing, food processing, and automobile manufacturing prowess.

About Us

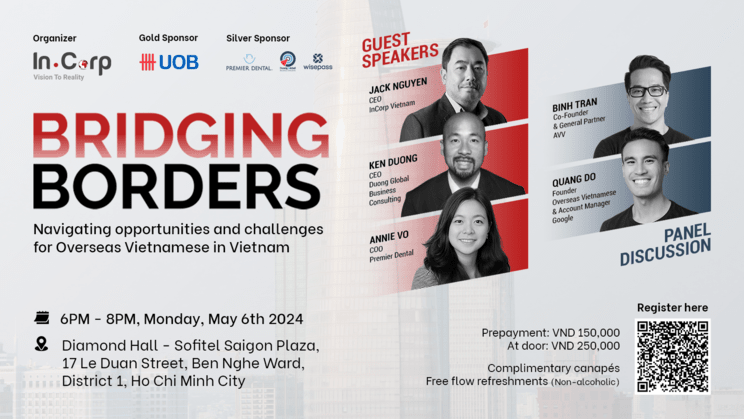

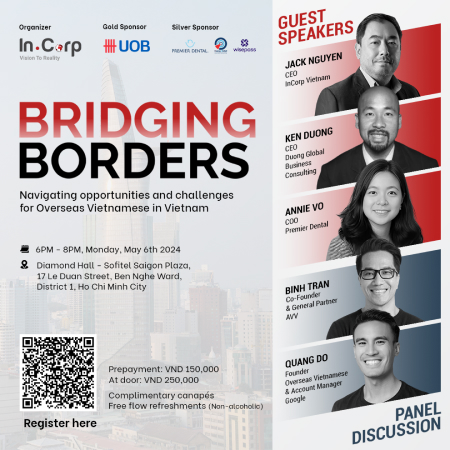

InCorp Vietnam is a leading market entry and corporate services firm in Vietnam. We are part of InCorp Group, a regional leader in corporate solutions that encompasses 8 countries in Asia-Pacific, headquartered in Singapore. With over 1,200 legal experts serving over 15,000 Corporate Clients across the region, our expertise speaks for itself. We provide transparent legal consulting, setup, and advice based on local requirements to make your business fit into the market perfectly with healthy growth.

Don’t take our word for it. Read some reviews from some of our clients.